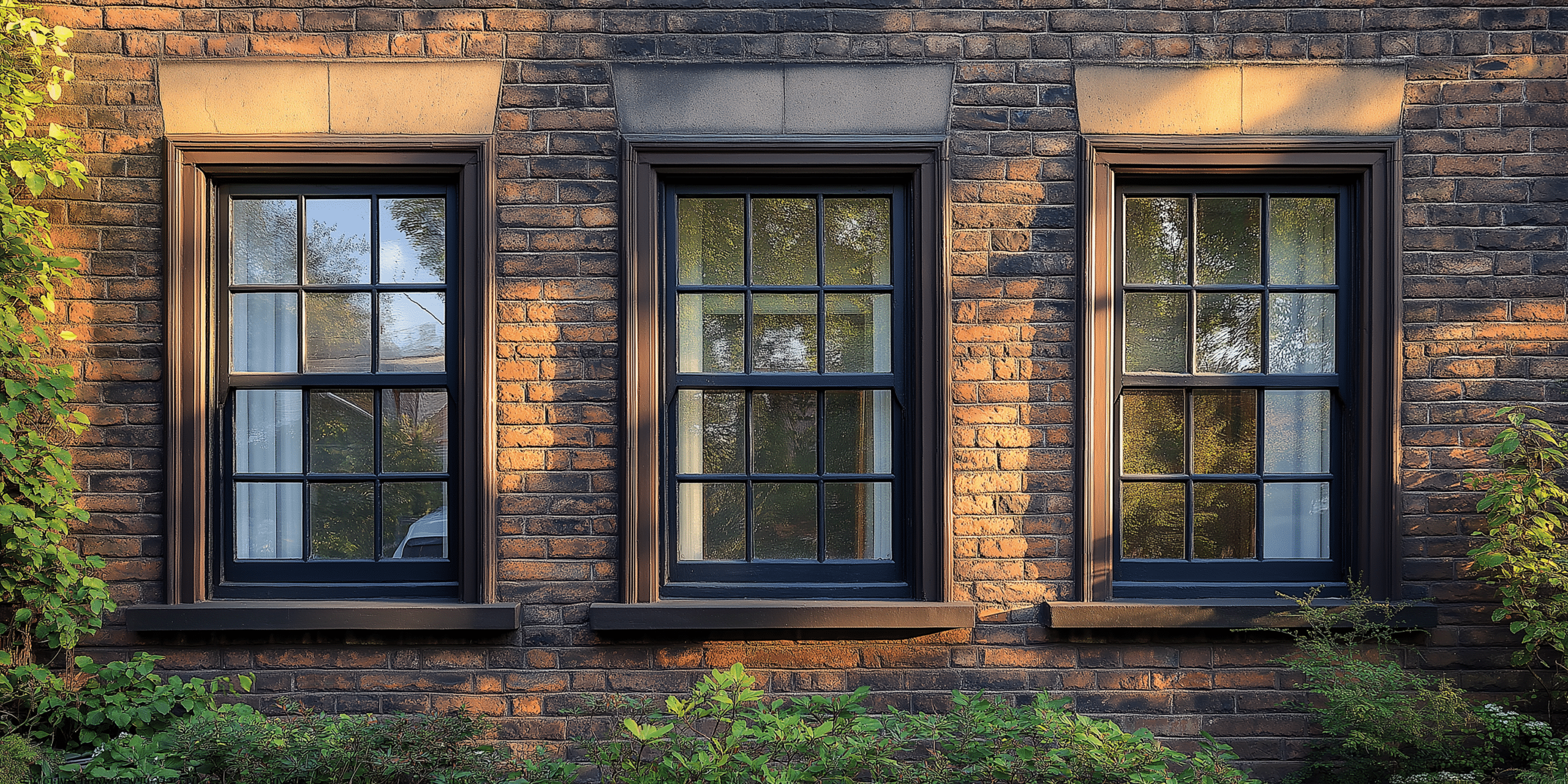

Introduction to Lead Came in Sash Windows

Lead came in sash windows serves dual purposes: structural support and decorative appeal. But what is lead came, and why is it so valued in heritage window restoration? Lead came, also known as lead stripping or leading, is a malleable metal strip that frames individual panes of glass within a larger window unit. This process dates back centuries and reinforces each pane, preserving the window’s integrity while adding an authentic period-specific aesthetic.

For restoration experts and homeowners aiming to preserve architectural history, understanding how to apply lead came is essential. According to sash window specialists, maintaining the original came work significantly contributes to the building’s character and value, creating “unique visual characteristics” often irreplaceable by modern equivalents. This technique extends the life of vintage sash windows and restores their character, maintaining the original charm that modern replacements often lack.

Historical Relevance of Lead Came in Architectural Restoration

Lead’s malleability and durability allowed craftsmen of the Georgian, Victorian, and Edwardian periods to create detailed, segmented window designs that remain structurally sound centuries later. These iconic period windows, such as the Georgian six-over-six or Victorian four-pane, are easily identified by their intricate lead framework.

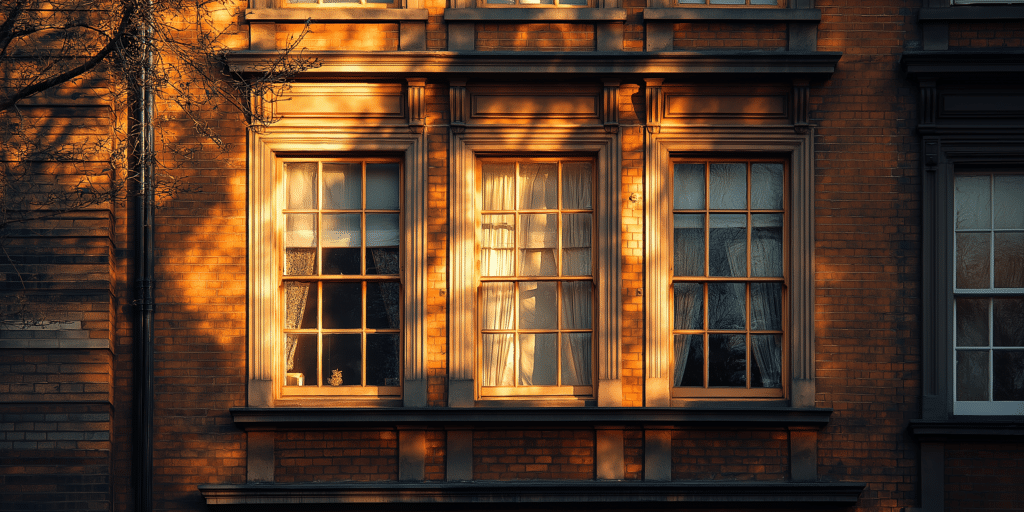

In modern-day restoration, using lead came continues this legacy by preserving historical accuracy. Lead’s unique patina and the “wavy” look of historic glass give heritage buildings their iconic character. Alternatives like zinc or brass may provide structural integrity, but for purists, lead remains the optimal choice for maintaining authenticity in heritage properties, contributing to a seamless historical appearance.

Materials and Tools Needed for Lead Came Application

Achieving precise cuts and firm adhesion begins with high-quality tools and supplies. Essential materials include high-grade lead came, solder, flux, and a cutting jig for accuracy. Premium lead came not only enhances durability but also resists environmental wear over time, ensuring the restoration can withstand the elements for decades.

Professionals recommend a lead knife, horsehair brush, soft mallet, and high-precision glass cutter for efficient handling and application. Additionally, using a soldering iron with variable temperature settings helps secure the lead joins, allowing for smoother and stronger connections. These tools are critical to achieving the tight, clean lines that exemplify quality sash window restorations.

Step-by-Step Guide: Applying Lead Came in Sash Windows

The process begins with a thorough cleaning, as dust and debris can obstruct measurements and lead to misalignment. Precise measurements are essential—measure each pane carefully, using a cutting jig to ensure clean, straight lines. Should the lead came be cut before application? Yes, pre-cutting each strip simplifies the installation, making it easier to fit each piece into place.

Next, the lead is affixed to the glass panes by gently tapping with a soft mallet, securing the lead strips without compromising their structure. For optimal stability, solder the joints where each strip meets, reinforcing the frame while preserving the integrity of the sash window. Restoration specialists note that achieving even pressure throughout the application process is essential to create a cohesive, polished look, especially in listed buildings or heritage sites.

Safety Precautions When Working with Lead

Lead handling requires strict adherence to safety guidelines due to its toxicity. Wearing nitrile gloves, masks, and safety glasses is essential to prevent skin contact and inhalation of lead particles. While PPE is fundamental, a well-ventilated workspace and frequent handwashing add further protection.

According to guidelines by the Health and Safety Executive (HSE) in the UK, following proper disposal protocols for lead fragments prevents environmental contamination. Professionals often monitor lead levels with testing kits for extensive projects to safeguard health, reflecting a strong commitment to occupational safety standards.

Techniques for Achieving Professional-Level Lead Came Application

Success lies in mastering clean cuts and precise alignment. A lead knife allows for smooth, exact trimming of edges, while a soft mallet helps achieve a snug fit between each lead came section. Consistent, gentle pressure ensures a flush fit, preventing gaps that could compromise the window’s appearance and stability.

Patience is equally crucial; taking time to inspect for irregularities and make adjustments helps create a polished, cohesive look. Restoration experts highly recommend this meticulous approach, as even minor misalignments can detract from the window’s authenticity and aesthetic quality.

Maintaining and Cleaning Lead Came in Heritage Windows

Once the lead came is applied, how should it be maintained for lasting durability? Regular inspections for corrosion and weathering are essential, particularly for windows exposed to the elements. Non-abrasive cleaning solutions help preserve the lead’s patina without eroding its surface.

Experts advise annual inspections to prevent minor issues from escalating, though windows in coastal or humid areas may require biannual checks. Applying a protective clear coat to exterior lead can help prevent oxidation, while indoor lead usually requires less maintenance in stable environments.

Alternatives to Lead Came for Sash Windows

For those looking to avoid lead, what viable alternatives exist? Zinc came and brass came are two common substitutes, each with unique properties. Zinc, for example, offers similar flexibility and visual appeal as lead but with greater resistance to tarnishing. While zinc and brass provide structural benefits, lead retains a particular patina and period-authentic look that restorers often prefer, particularly for historic preservation.

Choosing lead and its alternatives often depends on balancing safety, durability, and aesthetic goals. Zinc is a popular choice among restorers who prioritise longevity without compromising visual appeal.

Addressing Common Challenges in Lead Came Application

One common issue is achieving proper alignment, as even slight miscalculations can lead to uneven panes. Handful handling makes Realignment possible, though significant misalignments may require starting over. Warped or aged frames present another challenge, as they can complicate lead installation.

In such cases, reinforcing or repairing the frame beforehand can prevent issues and ensure a secure fit for the lead came. This approach aligns with best practices by experienced restorers, who reinforce weak frames to maintain structural integrity and visual cohesiveness in their projects.

Lead Came Application: Environmental and Regulatory Considerations

Lead usage is subject to environmental regulations, and requirements may vary by region. Consulting local guidelines before beginning work is essential to ensure compliance. Professionals often undergo certification in lead handling to meet regulatory standards, such as those outlined by the Health and Safety Executive (HSE) in the UK.

Proper disposal of lead remnants is also required by law to prevent environmental contamination. Experts suggest utilising certified lead recycling services for safe disposal, ensuring the restoration work remains environmentally responsible and compliant with legal standards.

Conclusion: Final Thoughts on Lead Came Application

Lead offers a unique blend of aesthetic and structural benefits, preserving the historical integrity of heritage buildings. By balancing tradition with modern safety practices, restorers ensure that each leaded sash window remains a testament to architectural history while meeting today’s longevity and environmental stewardship standards.

This approach not only maintains authenticity but also provides durability for generations, making lead came application an enduring choice in historic preservation.