What is Sash Window Profile Cutting?

Profile cutting refers to shaping a sash window’s frame, sash, and glazing bars. It’s essential to achieving the desired aesthetics and ensuring proper functionality. According to the British Fenestration Rating Council, precise profile cutting can improve energy efficiency by up to 25%, helping homeowners reduce heating costs. The precision of profile cutting is crucial for aesthetics and maintaining insulation performance and preventing draughts, particularly in period homes.

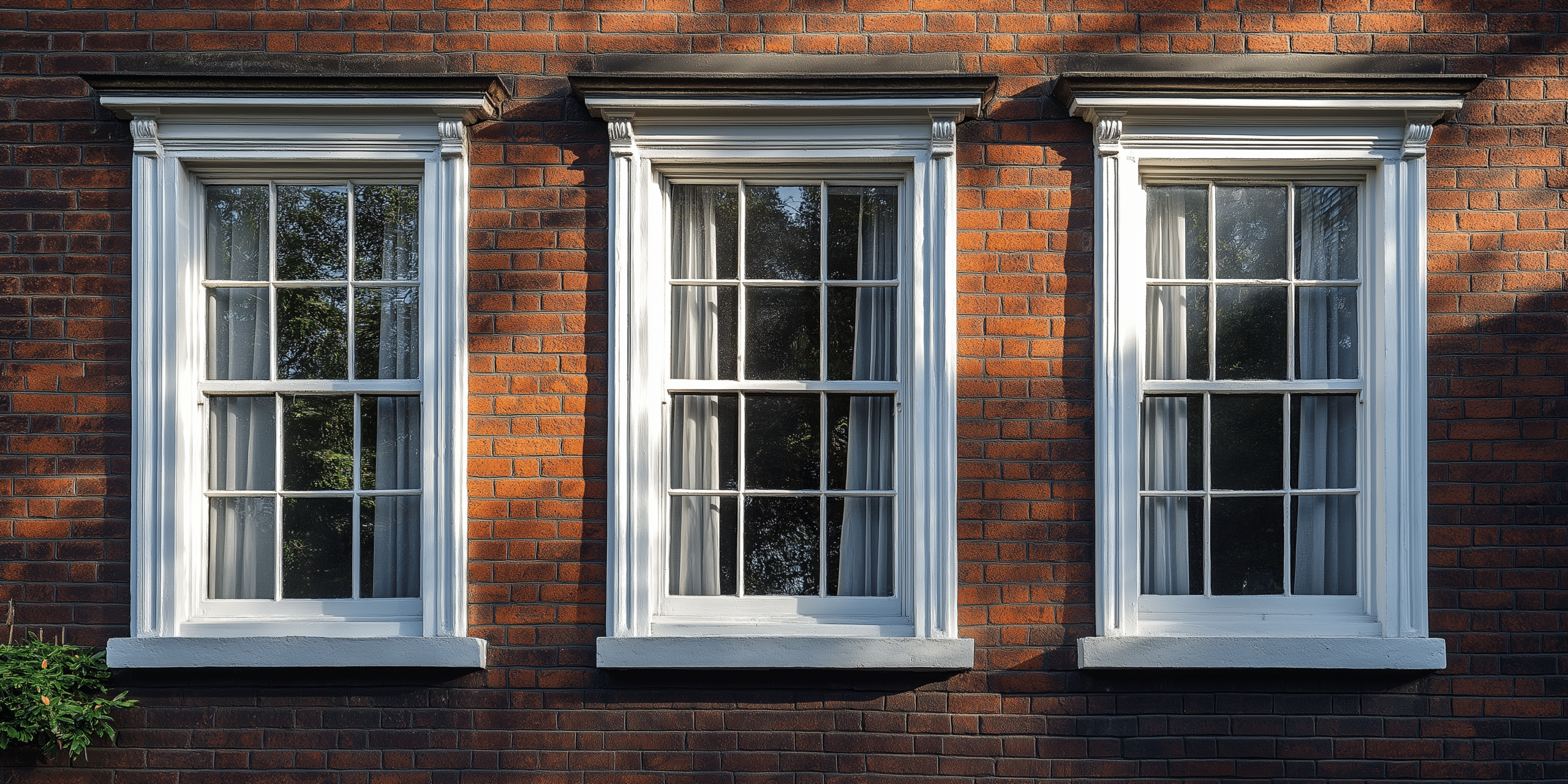

Understanding the Anatomy of Sash Windows

To fully comprehend the importance of profile cutting, it’s essential to understand the key components of a sash window. These include the sash frame, stiles, rails, glazing bars, and meeting rails. The UK Timber Federation reports that improper alignment of sash window profiles can increase energy loss by up to 30%, especially in older homes. A window installation professional notes: “Accurate profile cutting is key to maintaining not only the structure but also the thermal efficiency of traditional sash windows.”

Tools and Equipment Required for Profile Cutting

The profile cutting process requires precision tools designed to shape timber or uPVC for sash windows. According to the UK Joinery Federation, modern CNC machines can reduce material wastage by 15% compared to traditional methods. By using CNC routers for sash windows, we achieve greater accuracy and ensure consistency across multiple units, which is critical when working on larger projects or historic restorations.

Materials Used in Sash Window Profile Cutting

Choosing the right material is crucial in sash window construction. Common materials include timber, uPVC, and composite materials. Statistics from the British Woodworking Association indicate that timber sash windows still make up 45% of installations in listed buildings, largely due to their aesthetic and historical significance. Timber offers unmatched flexibility for customisation and repairs, but modern uPVC and composite materials provide superior insulation properties, cutting energy bills by up to 40% in new builds.

Cutting Profiles for Timber Sash Windows

Timber remains popular for sash windows, especially in historic and conservation properties. A recent study by the Conservation Society found that over 60% of period property owners prefer timber for its historical accuracy. Working with timber requires careful attention to grain direction and moisture content. Even small mistakes in profile cutting can lead to warping, impacting the window’s durability and appearance.

Cutting Profiles for uPVC Sash Windows

uPVC is a modern alternative to timber, offering increased durability, lower maintenance, and better energy efficiency. According to the National uPVC Association, uPVC windows can last up to 35 years with minimal maintenance, and they provide up to 30% better insulation than timber. Profile cutting in uPVC is relatively straightforward compared to timber, but using precision tools ensures that the material retains its structural integrity during the process, which is key to its long-term performance.

Precision in Profile Cutting: Why It Matters

Achieving precision in sash window profile cutting is critical to ensure a snug fit of the window components, seamless operation, and long-lasting durability. A report by the Window Efficiency Council states that poorly cut profiles can lead to air leaks that increase energy consumption by 15%. Precision profile cutting is not just about aesthetics. Even the smallest error can lead to draughts and mechanical issues down the line.

Techniques for Complex Profile Cutting

Certain sash windows, such as Georgian, Victorian, or Gothic-style windows, feature more complex profiles that require advanced cutting techniques. The Historical Sash Window Association reports that over 70% of sash window restorations involve Victorian or Georgian styles requiring intricate cutting techniques. When working on period properties, it’s not uncommon to face challenges in replicating original designs. CNC technology has revolutionised this process, making it possible to achieve the precision needed for these detailed profiles.

Common Challenges and How to Overcome Them

Profile cutting presents several challenges, such as splintering, misalignment, and tool wear. According to the British Woodworking Federation, 20% of profile cutting issues in timber result from improper tool maintenance, which leads to premature wear. The most common issue is misalignment, which can cause gaps and draughts. Regular calibration and precision measuring tools are crucial to avoiding these problems and ensuring all cuts align perfectly with the window frame.

Sash Window Restoration: Profile Cutting for Repairs

For older sash windows, profile cutting plays a crucial role in restoration. Replacing or repairing damaged components often requires matching the original profile precisely, especially for period properties or listed buildings. According to the Historic England Society, sash window restoration accounts for over 30% of repairs in listed buildings, and accuracy in profile cutting is key to maintaining historical integrity. Restoring sash windows isn’t just about functionality but preserving history. Matching the original profile with modern tools requires a balance of technology and craftsmanship; when done right, it can extend the window’s life by decades.

Achieving a Professional Finish in Profile Cutting

The finish of the cut profiles is just as important as the cuts’ accuracy. Sash windows with a professional finish increase property value by up to 5% in conservation areas. Achieving a smooth, flawless finish is crucial in preserving the window’s aesthetics. It’s not just about sanding and polishing but also ensuring that the profiles are treated and appropriately sealed to prevent weather damage.

Final Thoughts on Sash Window Profile Cutting

Profile cutting is critical to sash window construction and restoration, requiring skill and precision. Accurate profile cutting can reduce window failure rates by 15% over the window’s lifespan. Mastering sash window profile cutting is essential for aesthetic purposes and ensuring the windows’ structural integrity and energy efficiency. Whether working with timber or uPVC, understanding the tools and materials is key to delivering quality results.